Services:

Specialty NDE ServicesTruTank DR System - Automated Weld Imaging System

-

Stasuk Testing & Inspection Ltd is now providing automated tank scanning with digital radiography. The system operates at high speed acquisition of up to 35mm/s average rate on a 15mm shell. With strategic radiation shielding, the system produces extremely low dose radiation for the operator and allows adjacent work to continue without interruption. The company provides specialized scanners complete with operators, procedures and techniques which meet or exceed code requirements. The TruTank DR System operates with tracking for either horizontal or vertical weld imaging.

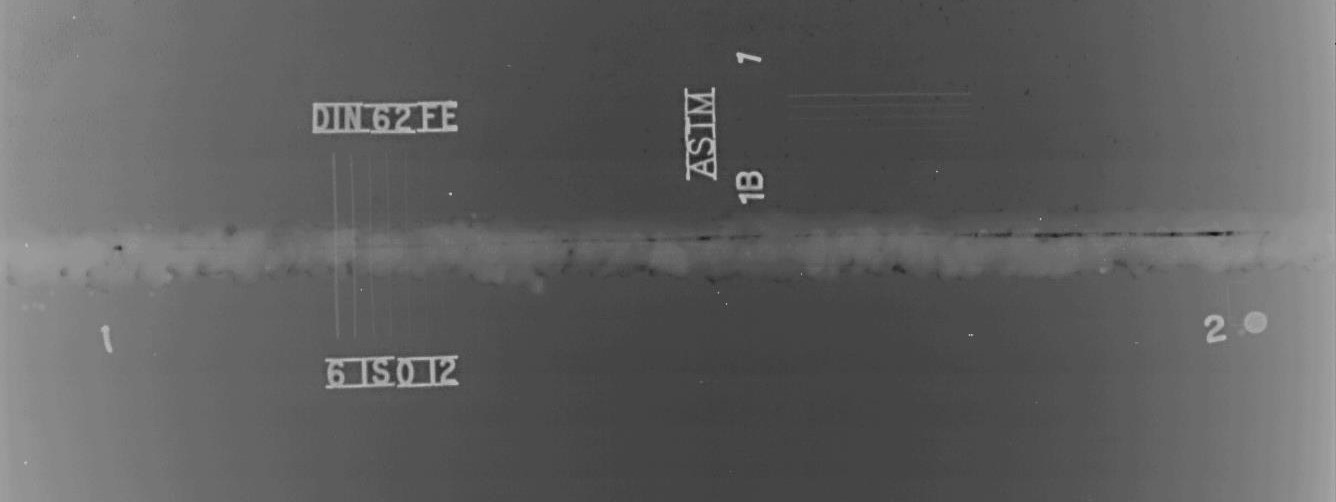

- The TruTank DR was designed to be used on large LNG storage tanks or large diameter vessels where 100% testing is required by code such as ASME VIII UW 51 or API 620 and 625 tanks but is adaptable for spot locations as well. With quick setup, mobility and the ability to keep up with erection and welding schedules, the production gains are significant. Unlike, other RTR type systems, the TruTank DR can scan within 4” of the bottom floor on the first course verticals. The Stasuk TruTank DR operates similar to conventional methods and moves in 250mm-300mm exposure segments at a 2s exposure rate. It is not influenced by tank movement, shell travel chatter or defect stretching sequences plagued by real-time RTR scanners. Our work on austenitic and high nickel vessels and tanks has brought a unique level of experience in this market and the TruTank DR system now allows us to easily show a welder or customer exactly what the technician is evaluating. Although digital image enhancement can be done with our evaluation software, the initial image meets the penetrameter and sensitivity requirements and therefor reduces the amount of overcalls on weld images which is common on other systems requiring image enhancement to view.

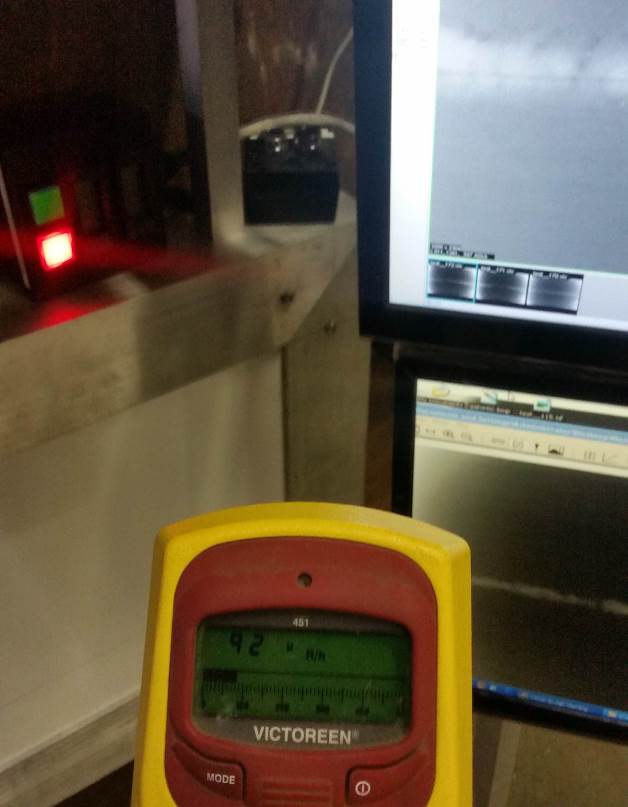

- Worker safety and maintaining an environment where workers need not worry about their radiation doses provides a new aspect to “low-dose” radiography operations. Working next to the x-ray system and panel was previously impossible. Radiographers would be expected to be working within a certain level of radiation hazard and the radiation dose was always considered a necessary evil. TruTank DR systems now allow workers to be adjacent to the X-Ray tube side, DDA panel or control system for direct monitoring in fields of less than 0.1mR/hr. The operator can safely ride with the scanner in a weld buggy style carriage and evaluate welds as it travels for quick results and minimal impact on construction schedules. Radiation boundaries are not required beyond the buggy envelope as the dose levels are far below the regulation levels. Welding carts or erection operations can continue to be working adjacent to the scanner buggy without restrictions.

Photo shows 92 µR/hr (0.00092mSv/hr) at the operators station within 12in of the weld face using 140kV -

**Download -Press Release - TruTank DR System

Contact us for more information