Project types

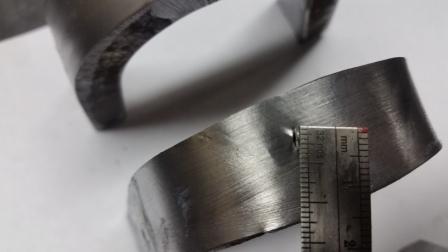

NDT Services & Technologies Quality Services to ASME, API, CSA, ISO and more...NDE/NDT Service Providor of Industrial Radiography, Ultrasonic, Magnetic Particle, liquid penetrant, Eddy current and advanced testing methods. Advanced AUT group and weldscan systems using automated corrosion scanners, phased array, TOFD and creep wave techniques. Our Heavy Wall Casting department uses proprietary 6MeV industrial linear accelerators, Ir192 and Co60 to produce code quality x-ray film for thick and thin materials. Our Destructive testing and engineering laboratories are able to provide welder qualifications, materials testing and fitness for service.